-

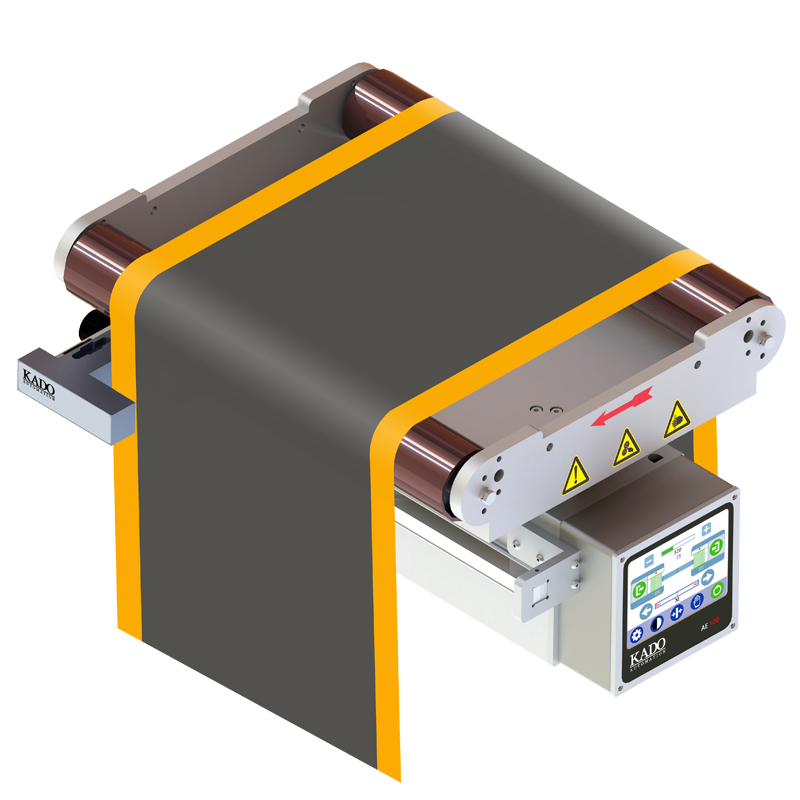

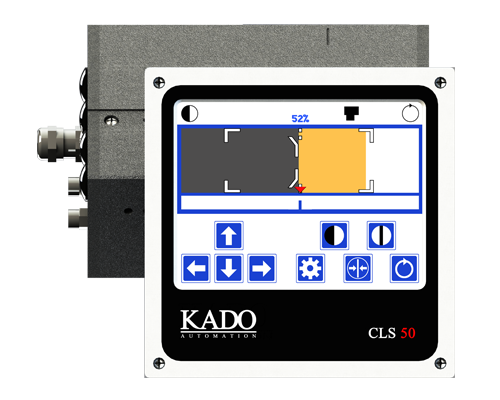

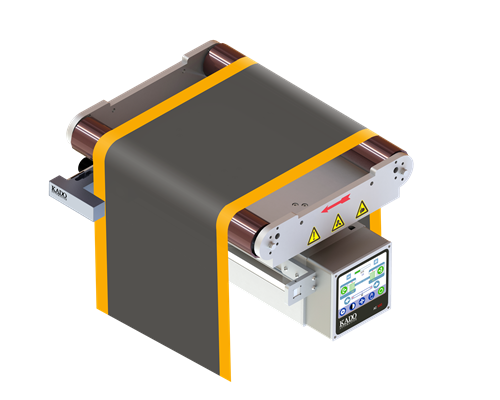

Web Guiding System

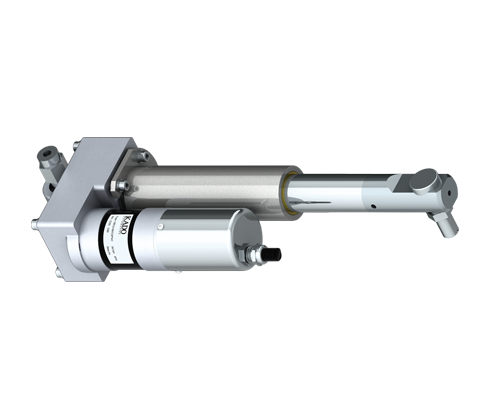

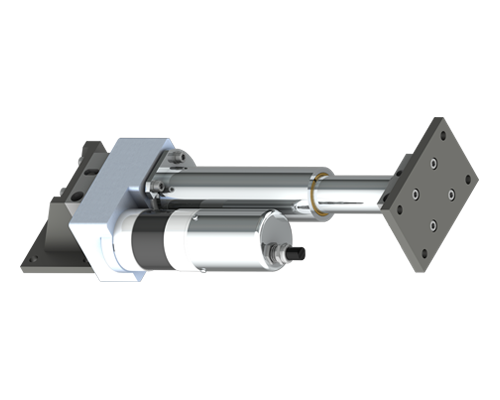

Nowadays, modern production equipment for strip coils is processed in various industries, and its production speed was unimaginable a few years ago. However, this increase in production speed must not be at the expense of product quality. Because the material deviates from the correct position, even a small error, the waste generated by any company can not afford. KADO's automatic rectification system ensures continuous and precise control of all types of strip materials in a variety of production processes, minimizing waste and downtime. We will ensure that your machine is running at full speed and normal.

See More >> -